Energy and Raw Materials from Waste

Recyclable waste typically comes in droves depending on the source. In the cities around the globe, individuals produce an average of about 500 kg of waste per year, which when applied to areas such as Paris, New Delhi and other populous regions, amounts to a daunting quantity of waste. Because many of these refuses are plastics, which have a heating value twice that of dry wood, there is plenty of energy to be extracted.

Through innovative processes like thermal waste utilisation, we are able to drastically decrease the volume by up to 90%, leaving just 10% of hazard-free substances. During combustion the waste is broken down releasing vast amounts of energy, then converted into electrical and district heating by our plants. The likes of natural gases, oils, and coal which all contribute substantial damage to the environment, are in turn saved, while modern flue gas cleaning keeps the environment clean.

Our plants serve as one of the primary facilitators in maintaining a balanced economy where recycling is paramount. Due to the innovations made possible by Kanadevia Inova Steinmüller over the past decade, 99% of metals contained in the waste can now be recycled. Certain sectors can now benefit from this achievement, as the raw materials still maintaining a good quality, can be recovered and utilised for vehicle construction, and the slag left over from the Waste to Energy process is salvaged for road construction.

Waste is compartmentalized into five separate categories given the source of the refuse. Household waste, commercial waste, hazardous waste, bio-waste, and sewage sludge are all divided before they are treated. Each category has a specialised process it must go through, all of which are possible with the use of our technology.

Proven particularly effective in high throughput rates of 5 -50 t/h per individual line, the high combustion temperature at 850 °C combusts the waste at a firm rate. In thermal recycling, the waste is continuously pushed forward on the steinmüller.grate surface and combusted. Due to the flexible application possibilities for different fuel compositions, the process is ideally suited for continuously produced municipal and industrial waste, substitute fuels, or other coarse-lumped, high-ash fuels.

Through innovative processes like thermal waste utilisation, we are able to drastically decrease the volume by up to 90%, leaving just 10% of hazard-free substances.

WE DEVELOP DESIGN SUPPORT BUILD A CLEANER FUTURE

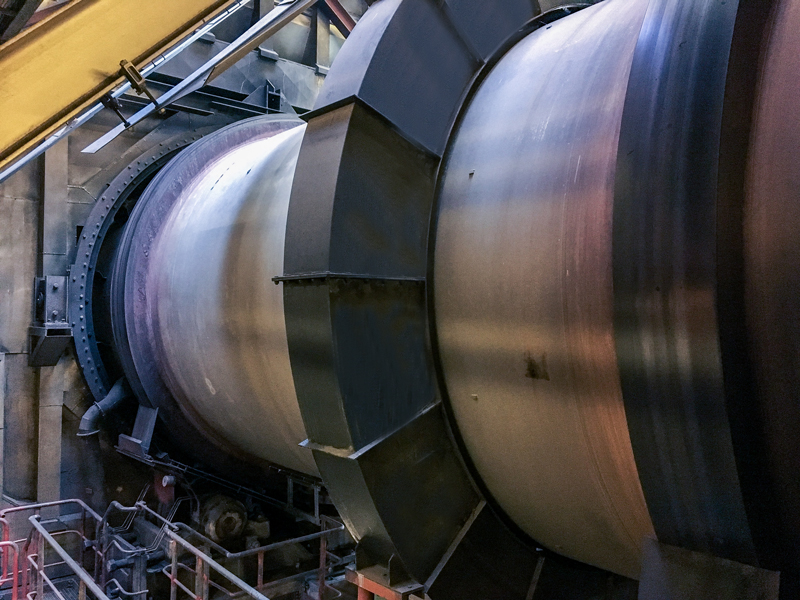

The term hazardous waste is used to label toxic, explosive, combustible, or corrosive substances, as well as waste containing pathogens, all of which pose severe health risks for people and the environment. The waste is treated inside facilities tolerable of high-temperatures. A rotary kiln operates at temperatures of 1,200 °C, ensuring the absolute destruction of all waste pollutants, whether they be solid, liquid, or gaseous matter.

Household Waste Produces Energy

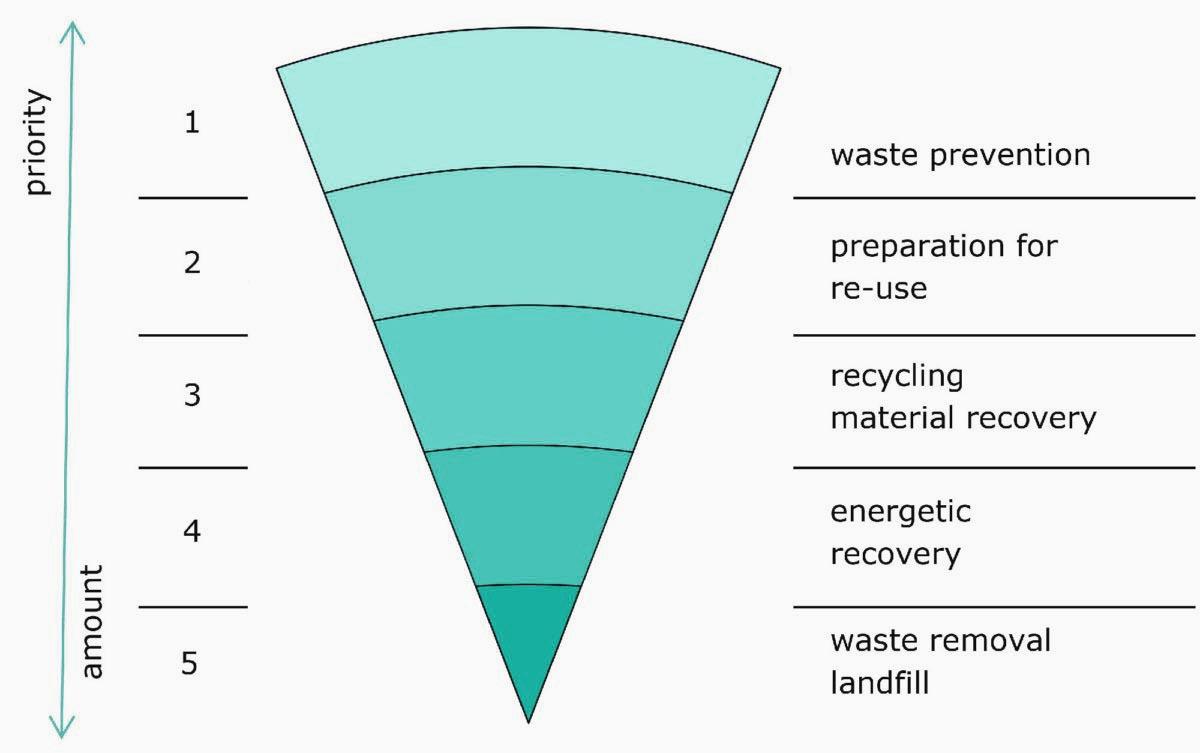

Produce durable goods in order to save raw materials, avoid environmentally-damaging materials in packaging, generally reduce the volume and weight of packaging.

Do not use disposable products, but rather re-usable products.

Recycling of previously used goods into other products, e.g. by melting metal

Thermal treatment of residual waste to generate useful energy, while complying with efficiency criteria

Thermal waste treatment without complying with efficiency criteria, disposal as landfill